In the ever-evolving construction landscape, offsite manufacturing is making significant strides as a way to push the industry forward. It’s also a valuable solution for minimizing delays and boosting precision.

To put it simply, offsite construction involves crafting a building’s parts in a controlled space away from the actual build site. Today, let’s explore the significance of offsite construction together, and delve into the role of laser scanning in refining this innovative approach.

WHY IS OFFSITE CONSTRUCTION IMPORTANT?

Offsite construction has become an important alternative process. As a result, many challenges found in traditional on-site construction methods are alleviated. Overcoming issues is an integral part of the construction process. Offsite construction has many advantages, these include:

- Reduced time delays – issues like weather delays and waiting on other trades are reduced, making the process more time efficient.

- Reduced labour shortages – less labour is required fitting on-site helping to save money.

- Reduction of waste and emissions – with more work done in a controlled setting, less waste is generated. This all contributes to a smaller carbon footprint

- Increased safety – having a controlled environment and fewer feet and machines on-site means the chances of accidents are significantly reduced.

According to gov.uk, studies indicate that the offsite construction sector makes up about 7% of the UK’s total construction output, contributing £1.5 billion to the nation’s economy. The adoption of Modern Methods of Construction (MMC) is on the rise, with the latest reports revealing that some form of MMC enhances 17% of new builds.

LASER SCANNING & OFFSITE CONSTRUCTION

At the heart of improving offsite construction processes is laser scanning technology. Advanced laser scanning surveys have reshaped the landscape of architectural and construction planning. No matter how intricate a building or piece of land is, laser-scanning surveys are extremely detailed and reliable.

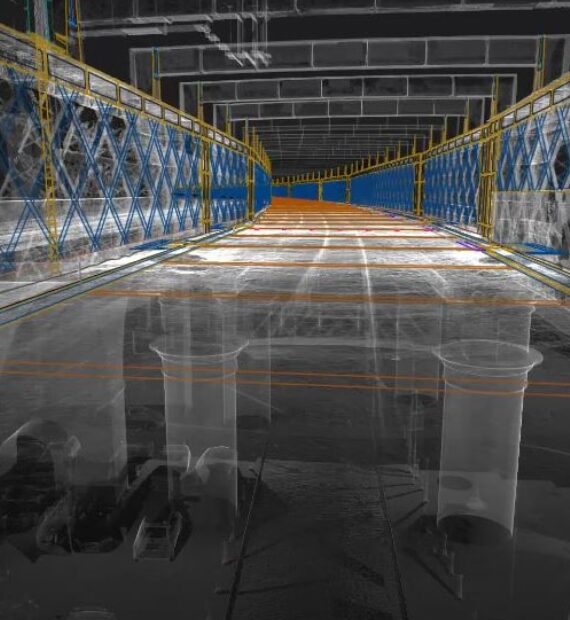

Data captured on-site is stored as a point cloud, which contains millions, or even billions of measured survey data points. Point clouds can then be transferred into a number of deliverables including 3D models and 2D CAD drawings. You can learn more about point clouds here.

But how does this help with offsite construction? Offsite construction, as above, has a number of advantages over traditional onsite construction. Laser scanning within offsite construction has the ability to enhance these benefits and more!

EFFICIENCY: SAVING TIME AND MONEY

Embarking on an offsite construction project is a journey where each detail plays a vital role in the successful assembly of components. With laser scanning, you get to construct your project virtually before laying a single physical brick. This method paves the way for meticulous planning and production, significantly lowering the risk of component mismatches later on.

Additionally, point clouds and 3D models empower everyone involved — from the architects to the builders — to visualise the project clearly and make informed decisions.

Laser scanning brings every inch of your intended construction space or existing structures into digital data with unmatched precision, removing guesswork and minimising the potential for human error. This reliability brings peace of mind to you, as you can trust that the components are designed to fit seamlessly when it comes time to bring your vision to life.

PRECISION: DETAIL IN THE DATA

As ever, precision stands at the heart of every successful construction project. Gathering site conditions with accuracy ensures that prefabricated components fit perfectly. Consequently, this reduces both the potential for errors and the need for rework. This meticulous approach guarantees a customised fit tailored to meet your unique construction needs.

Laser scanning data helps you plan for the future. By having accessible and accurate data, you’re able to highlight any potential risks before issues arise. This is particularly important in renovations, where the integration of new components with the old structure must be seamless.

INTERGRATION: SITE & SEQUENCE

Offsite construction seeks to seamlessly blend separate sections together, crafting a unified final product. Through the precision of laser scanning surveys, each section contributes flawlessly to the overall design. This ensures every piece comes together in perfect alignment, enhancing the collective creation. The journey from digital data capture to fabrication unfolds with the utmost care, therefore ensuring we can integrate the components without issue on site.

3D models from laser scanning surveys facilitate a collaborative environment where stakeholders can walk through the project in a virtual sense. It’s a tool that invites conversation and collective analysis, bridging gaps between architects, engineers and contractors. This means the prefabricated elements arrive and match the vision from day one.

DOCUMENTATION: RELIABILITY

As projects grow and change, laser scanning allows us to keep the 3D model fresh with new scans. This keeps our digital blueprint alive and kicking, perfectly mirroring the real-time progress and adjustments along the way. This enables decision-makers to adapt efficiently to new information, reducing unforeseeable issues down the line.

In the realm of construction and design, documentation is becoming more critical than ever, for two big reasons: meeting regulatory requirements and preserving historical records.

Currently, the data we gather from laser scanning serves on two fronts. Firstly, it plays a crucial role in documentation for regulators, smoothing the path to compliance and securing necessary approvals with greater ease. It directly supports processes outlined by regulations such as The Building Safety Act (2022) and contributes to the Golden Thread of Information, ensuring safety and integrity in every layer of the construction process.

For historical records, the accuracy that laser scanning data provides is invaluable. It captures the entire construction process in detail, preserving it for future reference. Historical records may reduce survey costs down the line should the building specifications evolve. By storing this historical data, we’re not just keeping tabs on plans and site conditions; we’re safeguarding the story of your project, making sure every important detail is recorded for posterity.

CONCLUSION

Offsite construction has truly blossomed within the AEC industry, proving its worth through notable growth and an expanding market share in recent years. When we pair it with laser scanning, offsite construction really takes off, becoming more predictable, manageable, and refined.

This combination serves our clients by offering undeniable clarity and confidence in their projects. We genuinely empathize with the pressures that industry professionals face daily. Incorporating laser scanning into the offsite construction process unlocks new levels of efficiency in both time and cost. This advantage extends not just to you but also enriches your clients, fostering enduring relationships along the way.

Don’t just take our word for it! Feel free to fill out the quote form below or get in touch with our warm and passionate team here. Finally, we’re here to guide you through every step, ensuring your project’s journey is as smooth and successful as possible.